FInal steps in the assembly of the rudder bottom fairing. The holes were drilled #19 and now need countersinking. I will attach these with stainless #6 screws and tinnerman washers.

Countersinking in epoxy fairing is no fun. It's very easy to chatter the hole, the material is very thin do anyway, the hole gets slightly enlarged. On top of that, the epoxy wears out your countersink bit. All the more reason to hate this job. I used a thick backing plate in aluminum with #19 hole and slightly countersunk to guide the countersink bit.

The front fit looks smooth. I may install an addional screw to fixate the tab in front of the rudder horn.

it looks very nice on the airplane, the top line fits snug with the bottom of the rudder skin.

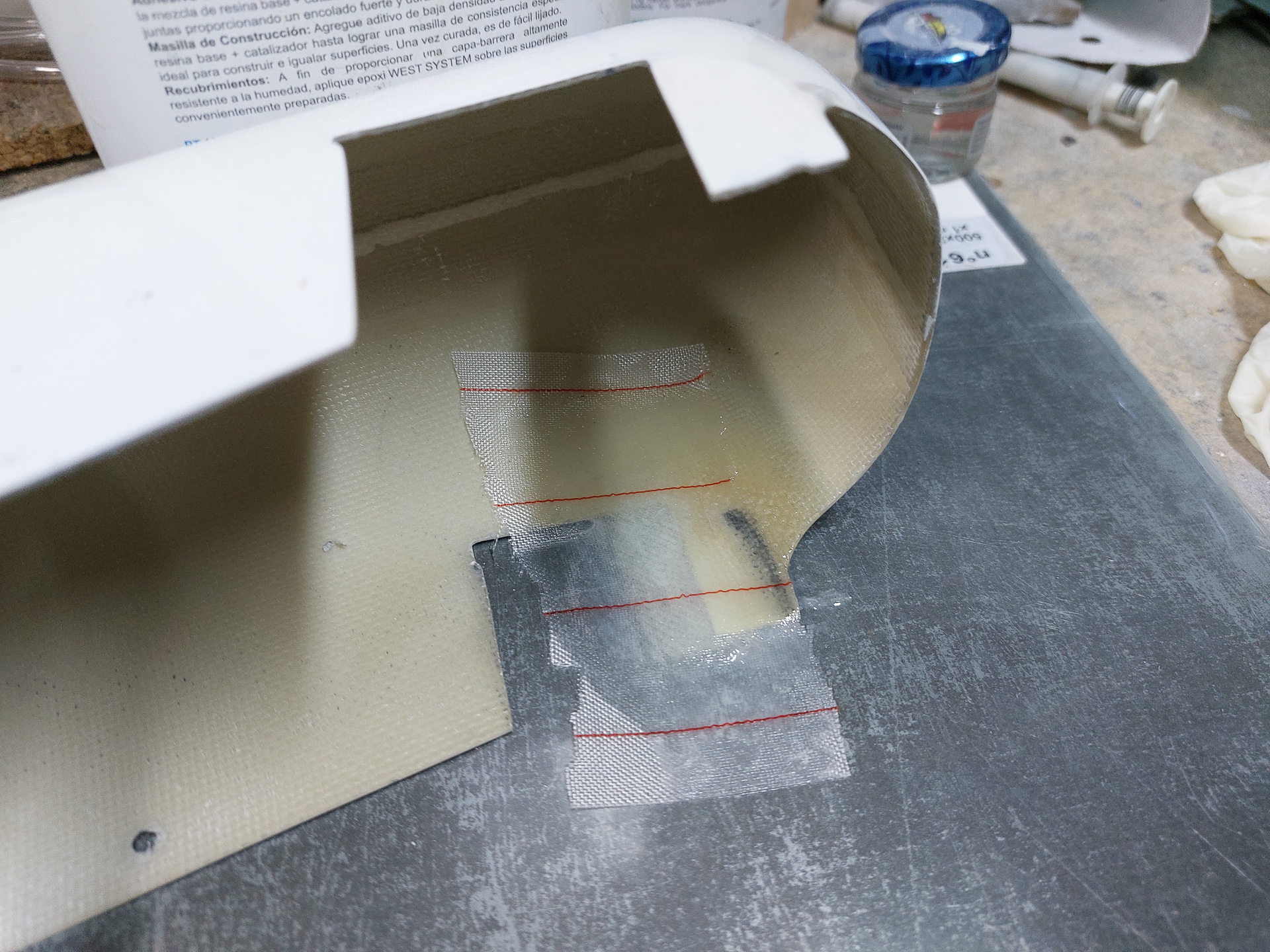

I removed the fairing and layed up some fibre cloth to close the small gap I had created during fine tuning and cutting.

To finish the session, I started making a small aluminum adapter that will hold the Aerosun Suntail light to the rear of the rudder