A couple of weeks have gone by. I had a hip surgery on 6th of December and walking on crutches since. As I'm starting to get a little more mobile, I was thinking of things that I could do on the plane with same extra pair of helping hands. One of those things was wiring the fuel senders.This has been on my mind for a while, thinking of the stupidity I had to fasten the tanks without attaching an electrical signal wire to the Stewart Warner fuel senders. These are of resistive type and only required one wire running back to to cockpit. The GND wire is locally grounded to the structure.

I had the tanks screwed and bolted on but the fuel sender is located in the back of the second bay. There is no way to access that than to remove the tank agin.

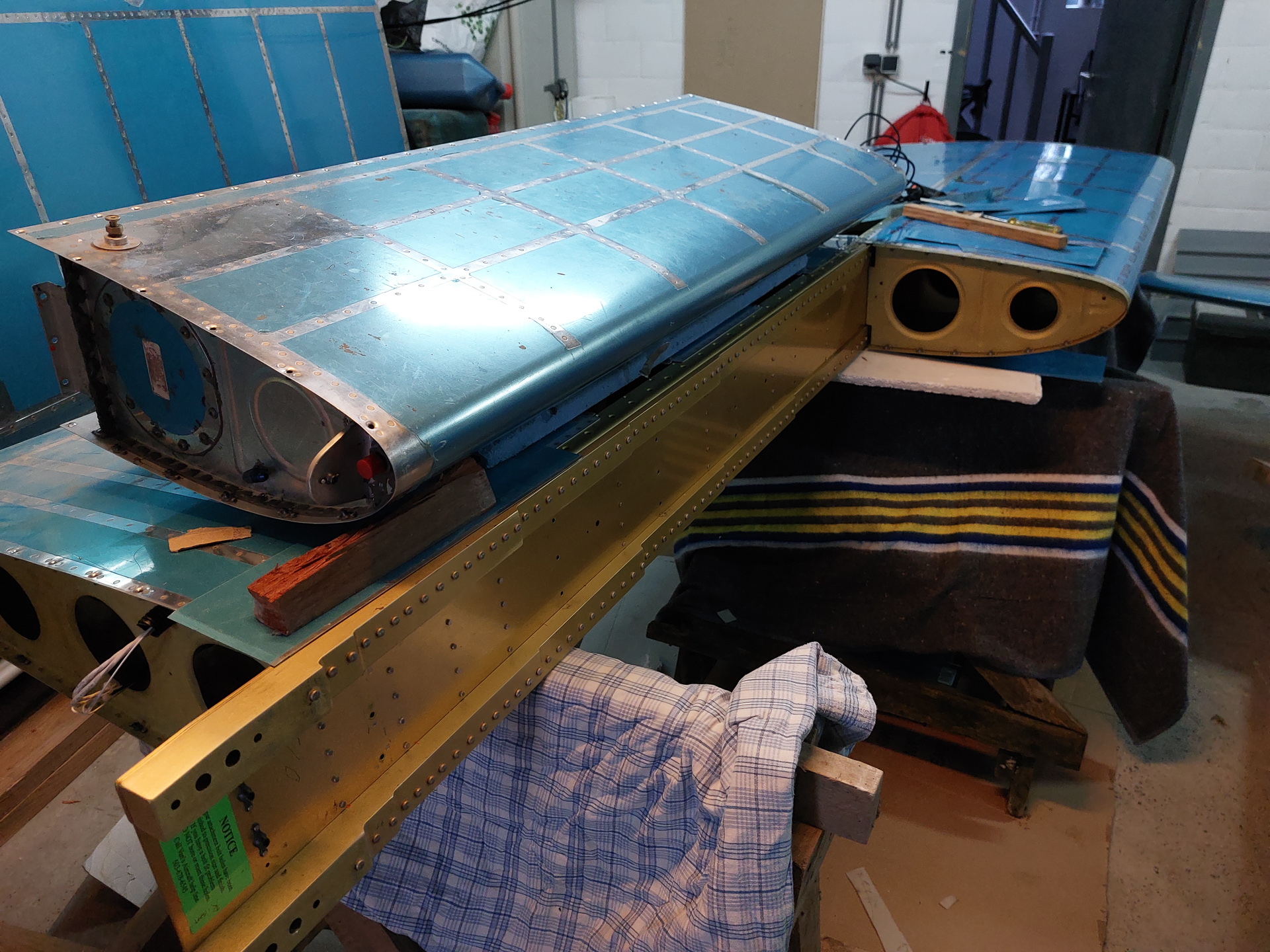

I thought this would be an easy task. Just remove some screws and bolts and off they go. Well, that turned out to be a different story. With all the screws and bolts removed, the tank didn't move 1/64 of an inch. The dimples being in the countersunk holes all the way along the spar and sides make that the take remains in a thight position. I had to slide thin pieces of aluminum strip underneath the edges to push them up and then gently tapping along the rear edge with a long woodblock and rubber mallet. Still not a lot was moving. Until with some extra taps I could get some movement on the middle of the wing as the forward skin can about 1/32 of an inch forward of the other outer forward skin. I then used a long screwdriver (padded) and was able to pull the tank forward and it gently came loose.

long story to say: don't worry, even if some screw would fail on this, there is no way the tank is coming of your wing. I hope this was the last time they had to come off as it turned out to be a full day task just for one.

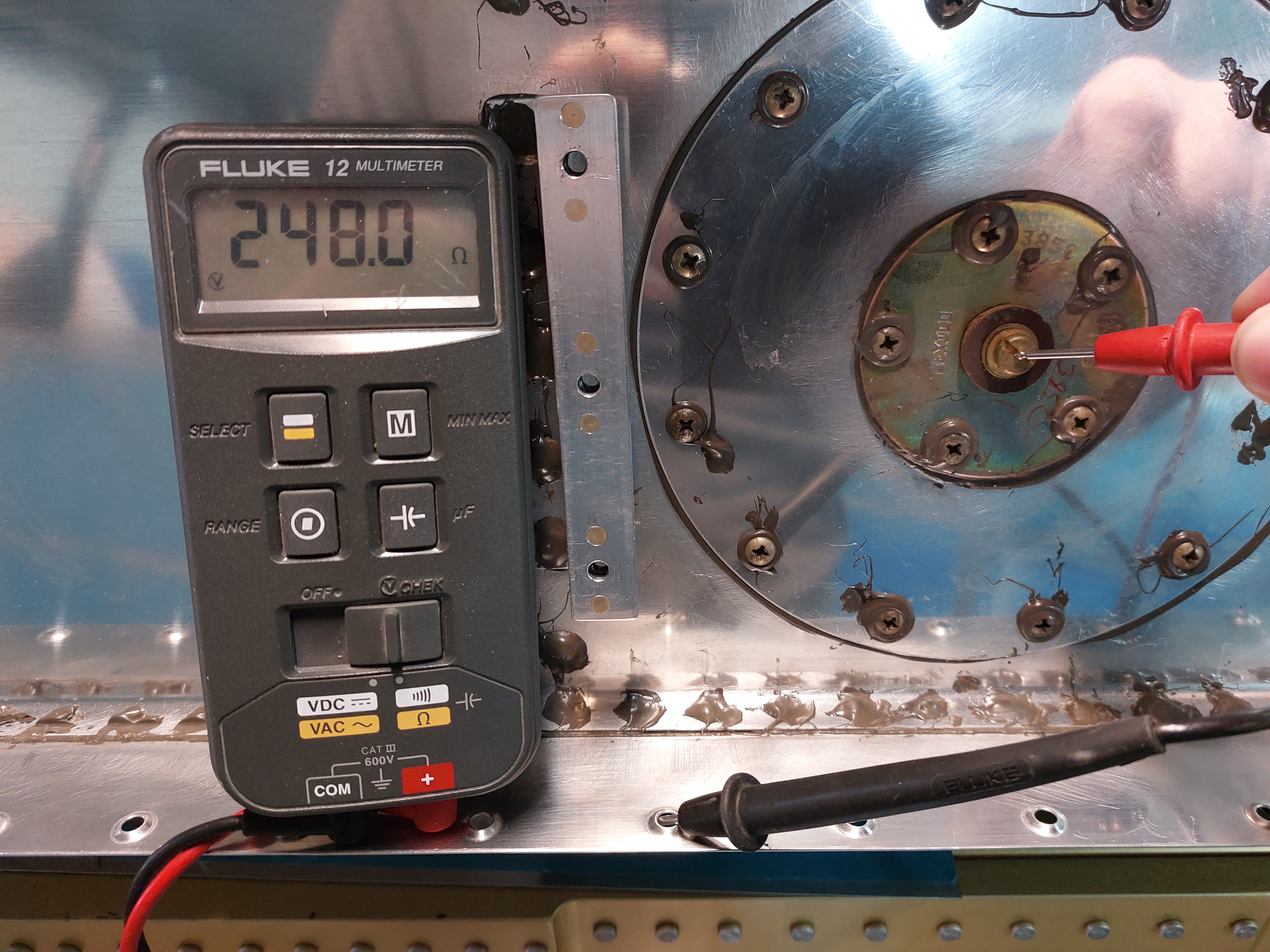

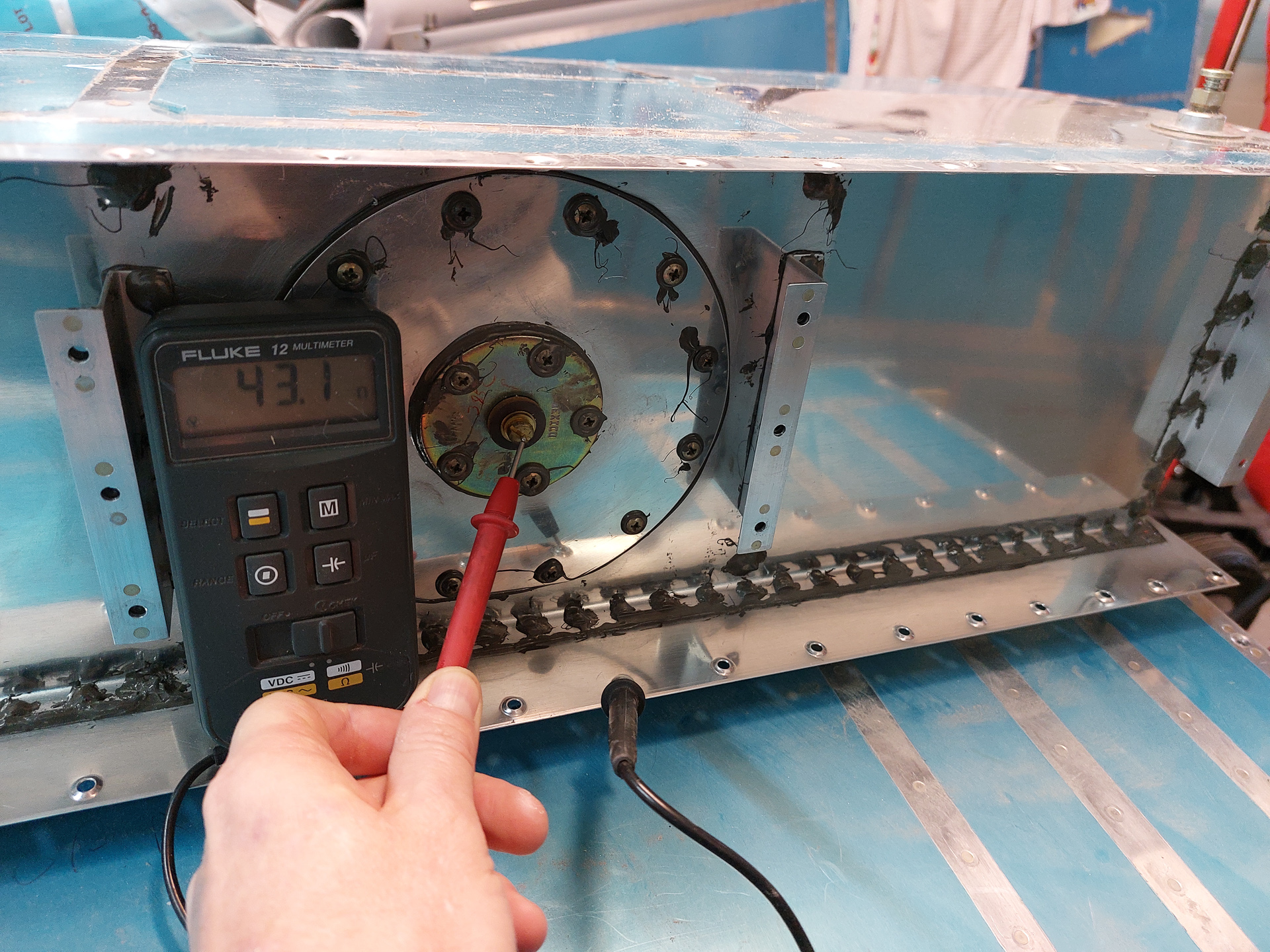

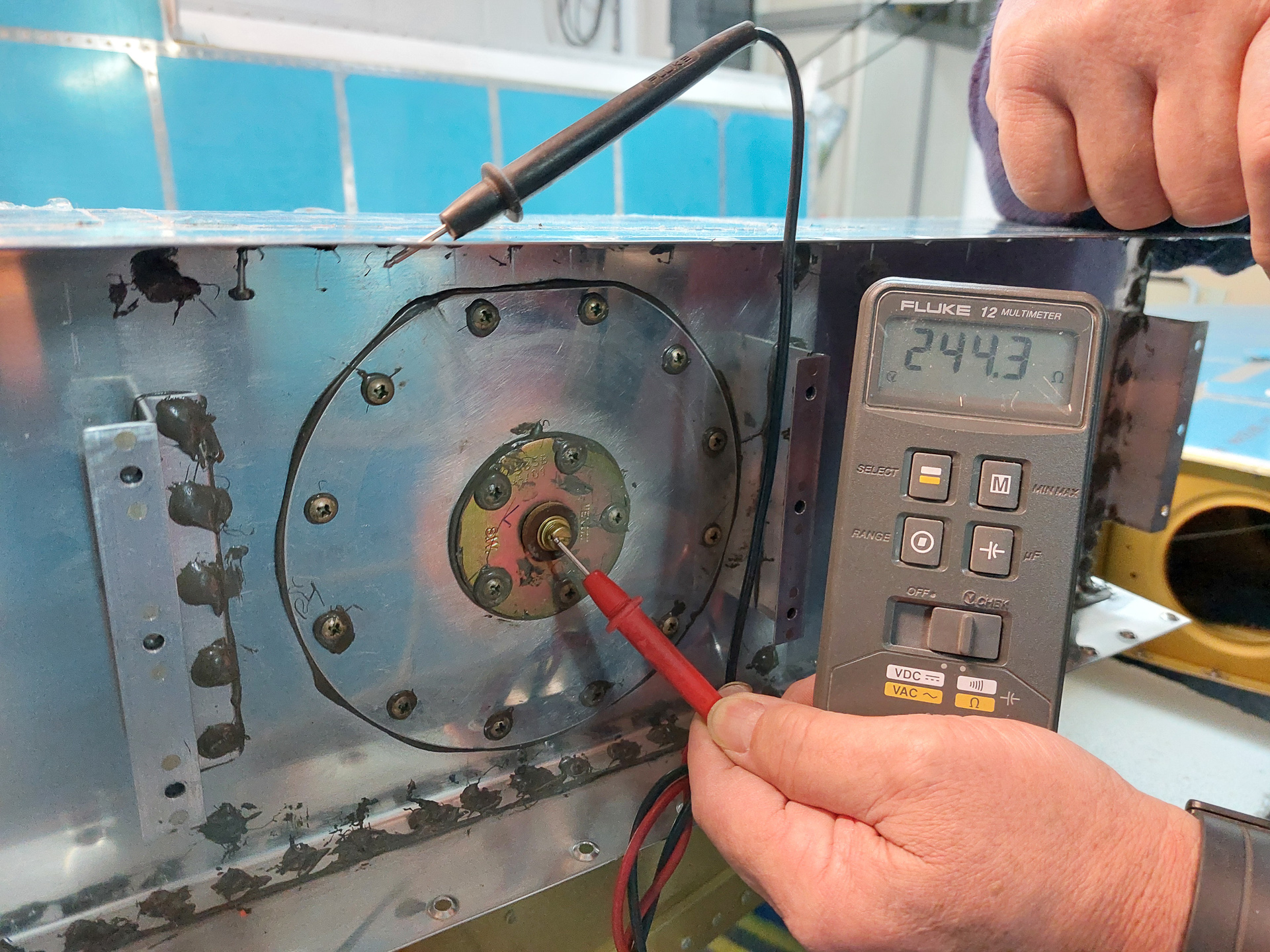

I then tested the resistance reading with the tank in both positions. I had done this before when I closed the tanks so no need to break the tank sealant and move the arm. turning the tank upside down will move the arm down and allow me to make the fulle or empty reading. The max resistence on the tank-emptyside was 248 ohms, and I had 42 ohms on the full positions.

The expected range of these is to be between 33 and 240 ohms so I'm definitly on the good side here. I'm not 100% sure at this time but I believe these values get calibrated in the Dynon EMS system.

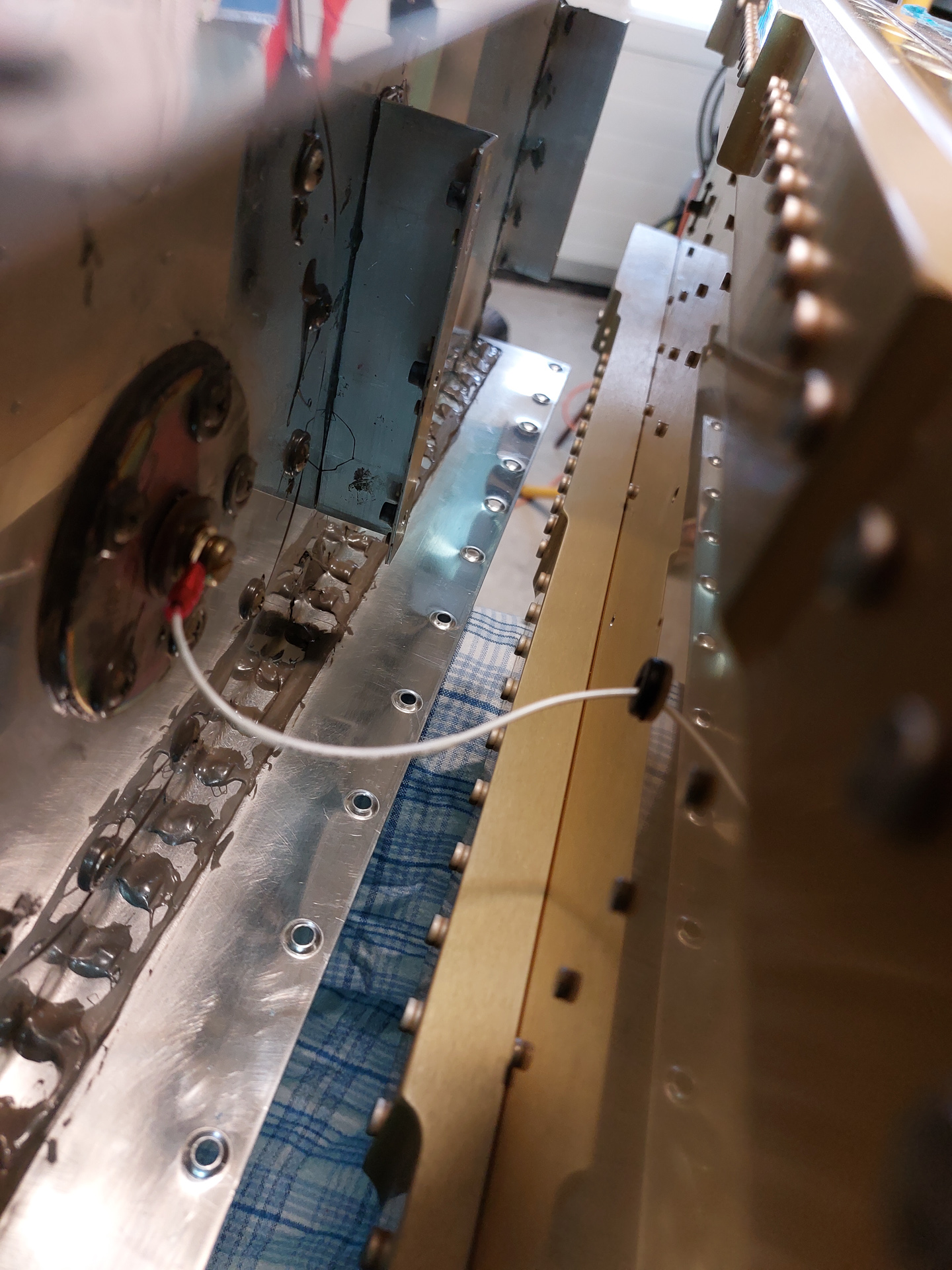

Connected the single wire and pulled it through and already existing tooling hole in the spar with a bushing

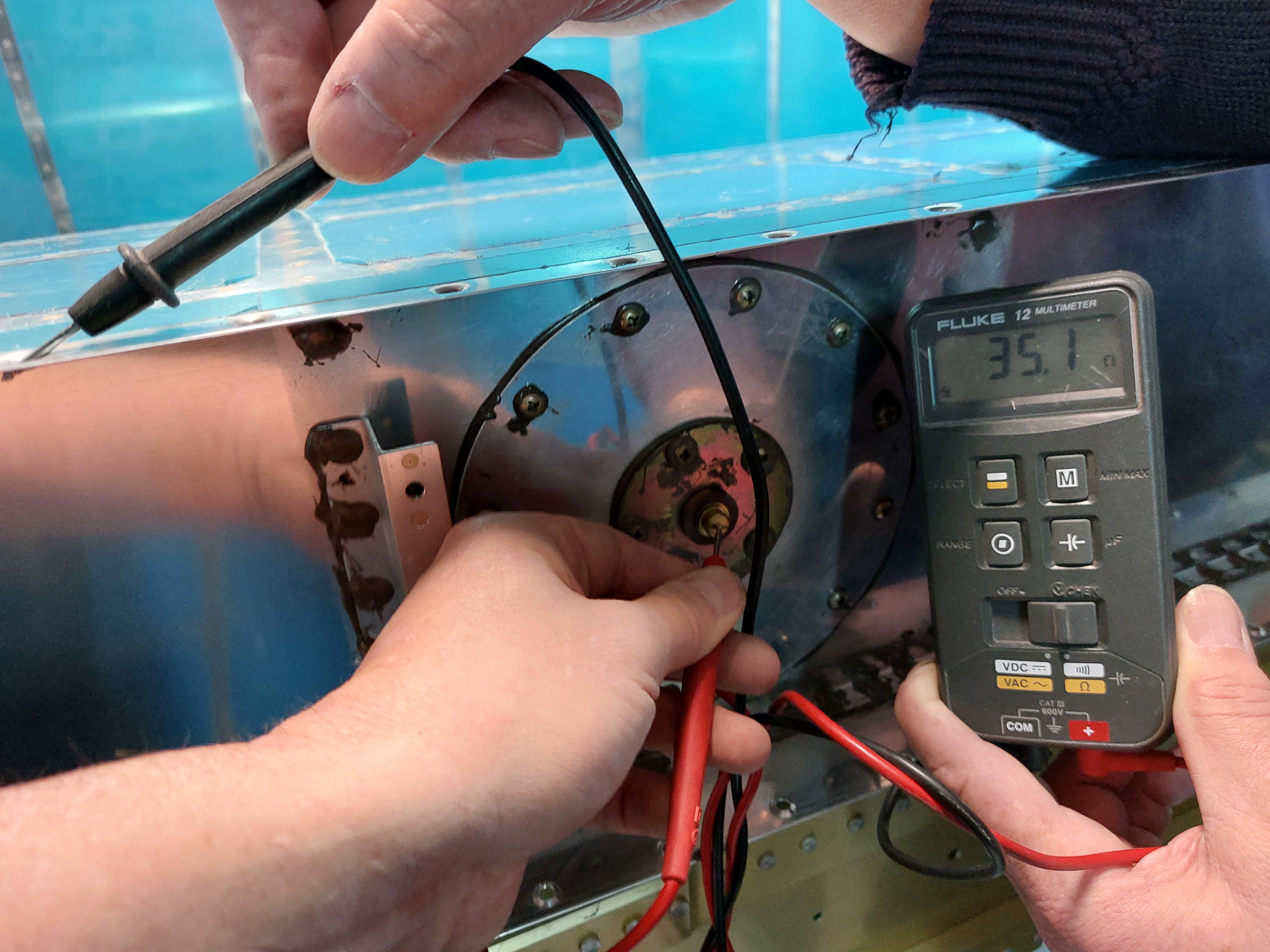

The next day, I did the same job on the other tank. Readings here varied between 35.1 ohms full and 244.3 ohm empty

There is only one connector for the signal wire which is on the screw in the middle of the sender. The GND is wired to the structure on the inside of the tank within the fuel sender mechanism.