05/05/2025 - Bringing the engine home from PMM - 4h

Big day I have long time been waiting for : my engine came home and is now in the workshop !

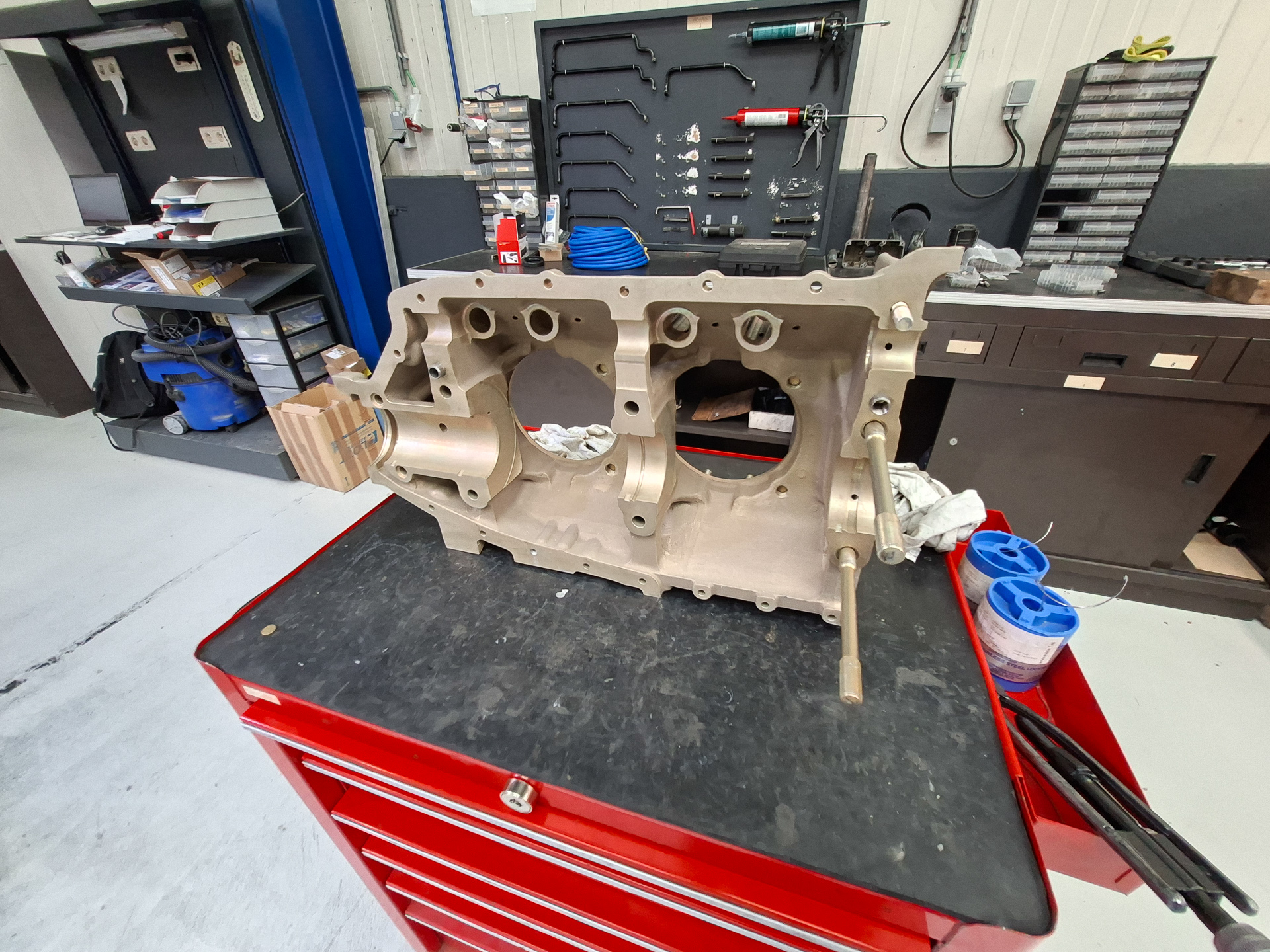

We used a Ford transporter to go and pick it up at PMM Wingservice. They had fixated the engine on a pallet supported by some wood blocks in the front and standing on the cold air induction sump in the bottom. Some straps around the case keep it on the pallet and stop it from moving. Moving it into the car was easy with a clark. We used straps to secure the pallet in the car so that it can't slide.

At this point, nothing is attached to the bottom of the engine. No starter, no alternator, no throttle body and this is also the way it has to be brought back when it will go on the test bench.

After a 2 hour drive, we arrived at the workshop. Boy this thing is more heavy than I anticipated. We moved it by sliding on the ground and drove the car all the way into the garage.

The engine hoist slided underneath and we were able to lift the engine out of the car. The engine hoist has a V shaped base so you can't just put it on the ground and be done.

We had to bring it down on the V shape base and then carry the pallet with 3 persons to the final location.

Here's Matthias, my son posing with the engine. In the initial pictures of my workshop, you can see him as a 5 year old toddler. That says a lot about how much time I have spent and how many years have lapsed since the beginning of this project. Sometimes I curse and wish the thing to hell, but I never regretted starting on this journey. The only way from here is up, literally...