I have been looking at my vertical stabilisor alignment in relation to the fuselage and I am not satisfied with how the alignment is. I noticed that the elevator is too much tilted backwards towards the top and this makes that when installing the AN3 bolt on the elevator stop angle, the elevator rear spar is getting pulled towards the rear bulkhead of the fuselage. I found out that the reason for this is that I installed the optional F-781B spacer spacer/doubler on the F-781 vertical stabilisor attach plate in the front between the F-781 and the VS-702 front spar. Looking at it now, I believe this was not required and it actually pushes the elevator backwards and away from the F-712 bulkhead.

Scratched my hair for a while, trying to figure out what this means for the allready drilled holes in my empenage to fuselage alignment.

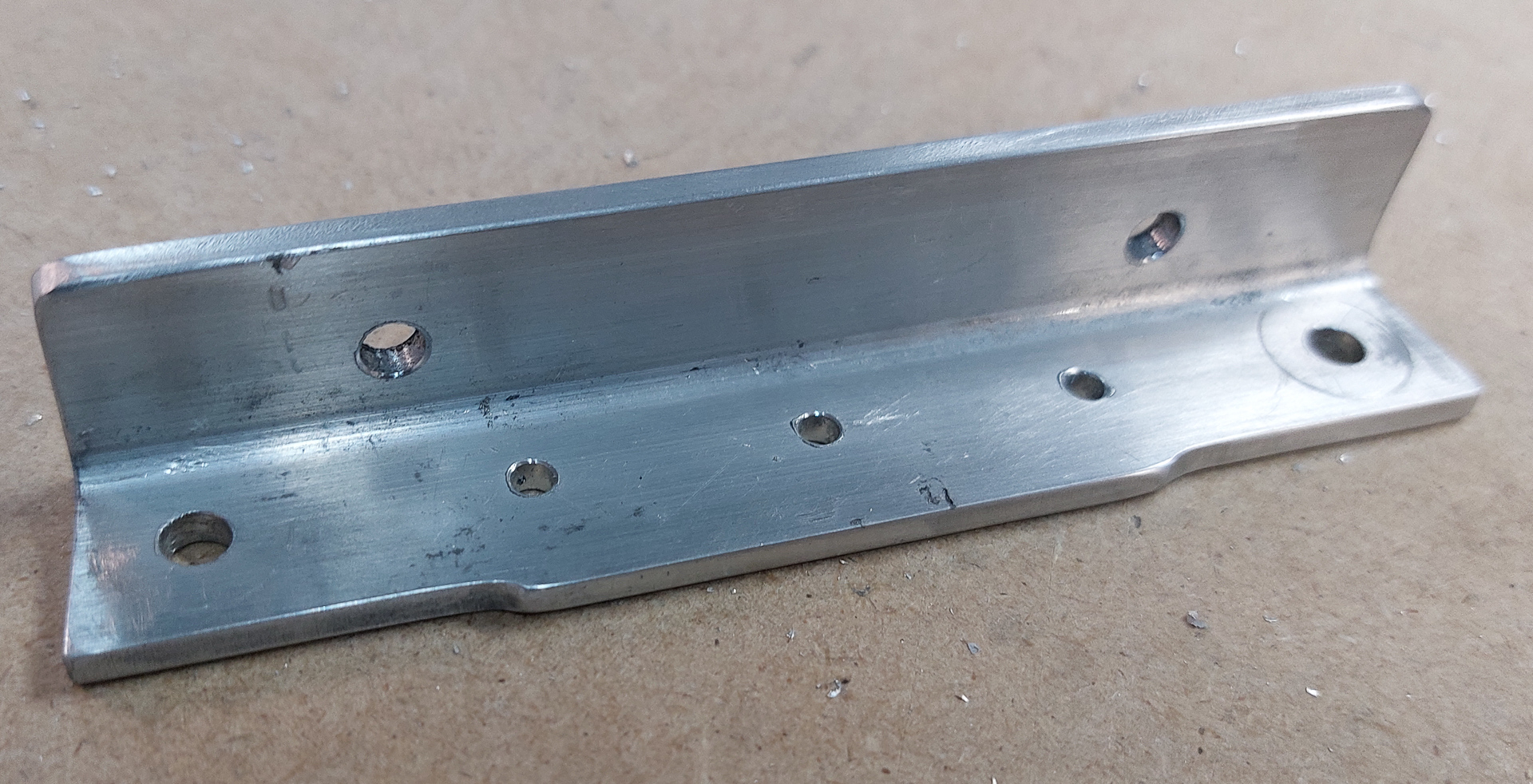

I decided to go for the best solution which was to remove the doubler and recheck the aligment. The only holes that would not match anymore were the 2 x AN3 bolts through the F-712D up elevator stop bracket. Which means that that bracket will have to be remade. Not a very big deal, just a lot of work.

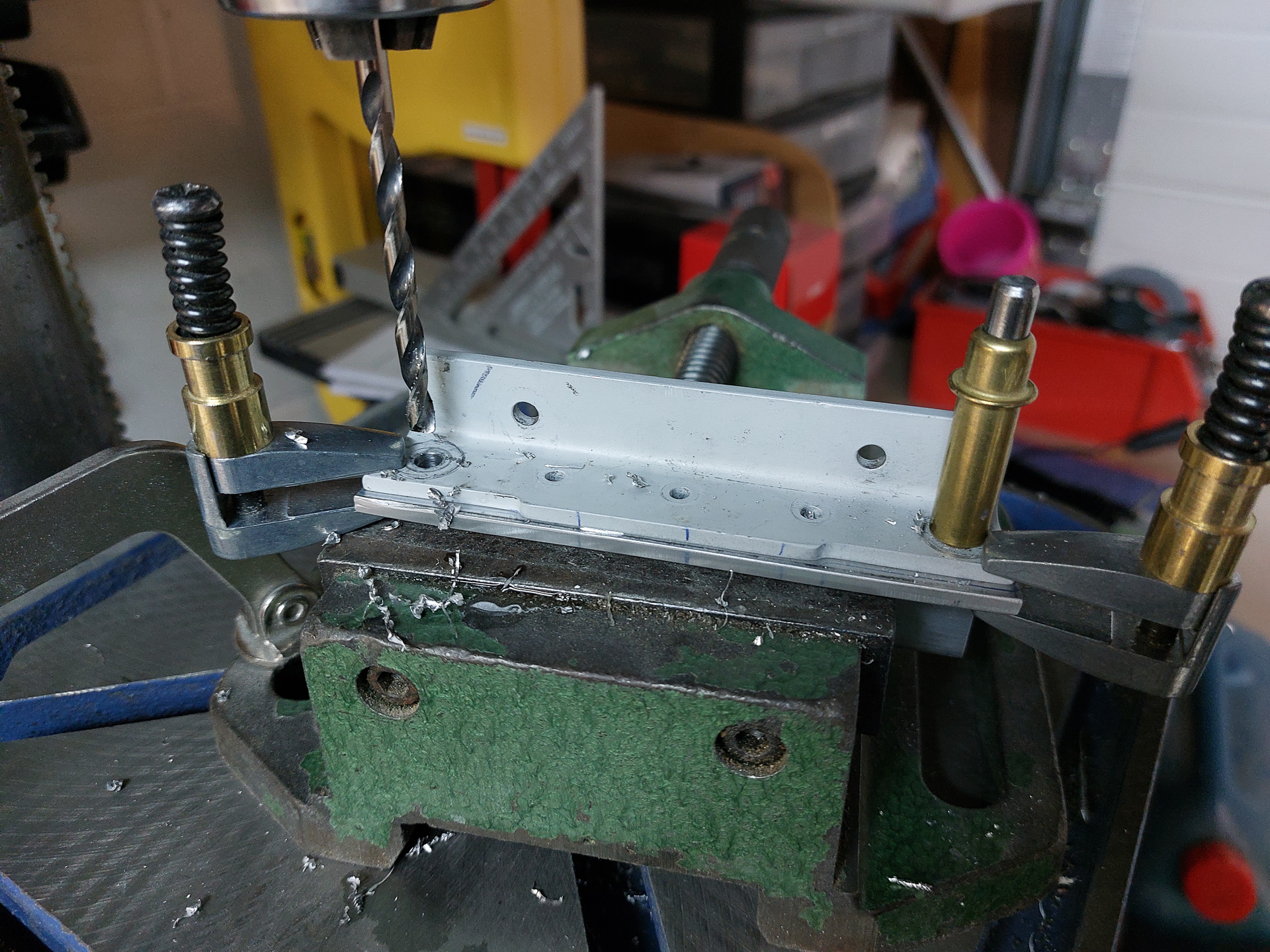

So I started with removing the vertical and horizontal stabilisor from the fuselage and drilled out the rivets that held the up elevator stop in place. Fortunatly I'm good at drilling out rivets and all holes looked unharmed when removed. Then I cut a piece of angle and copied the form on the new angle. Some cutting and grinding later, I could place the new angle in the vise, lay the original piece over it and match drill the 5 holes in the angle that hold the up elevator stop to the F-714 deck.

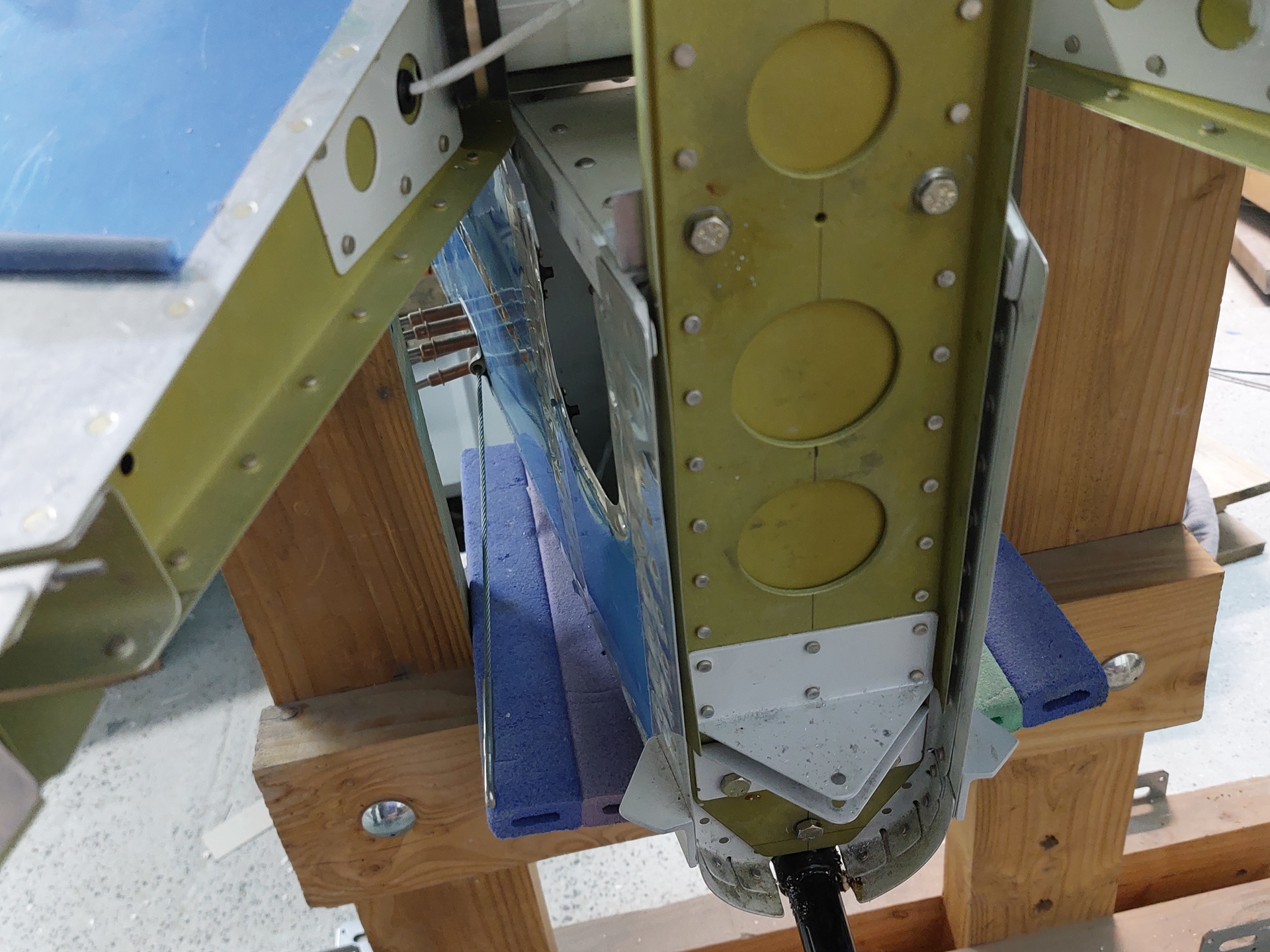

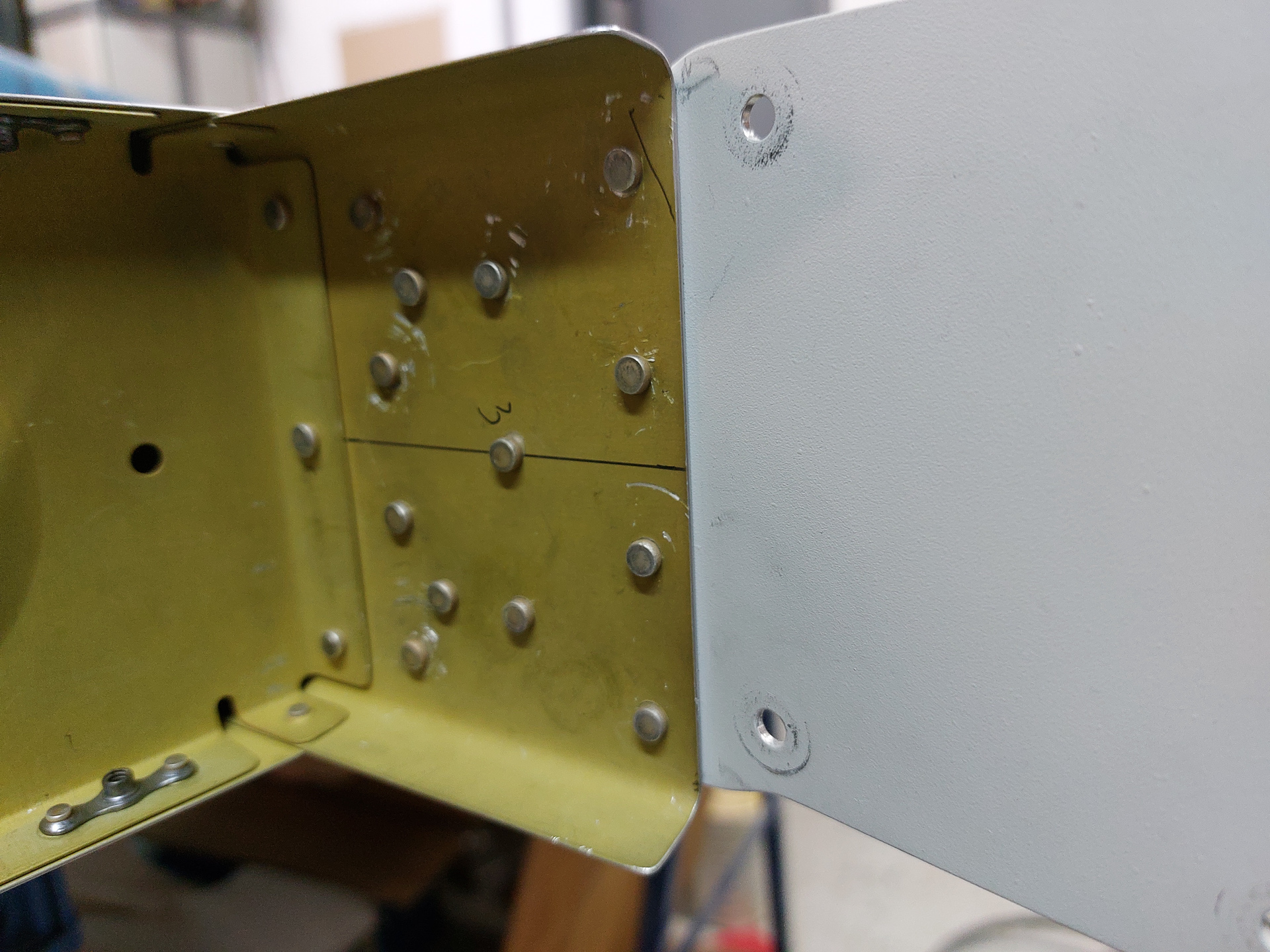

Next I did a test fitting on the F-712 bulkhead. Notice that I left the vertical leg of the angle way too high. This still has to be cut but since I didn't know how the hole alignment would have shifted by the move, I decided to postpone the cutting of the vertical leg until I got the exact location of the new AN3 holes that attach the rear spar of the VS. I also reinstalled the HS and the elevators to get a better idea of the amount of material te remove from the stop to allow the up deflection of the elevator.

Top view of the same. The fasteners are not attached, this is just for alignment as the angle still needs to be primed.

I then drilled out all the rivets from the frontspar of the VS and attached the VS-702 front spar with cleco's to the F-781 VS attach plate. When reinstalling the VS to the HS and bottom of the F-712, you can see in the image below that even without AN3 bolts in, this match is much better and there is no more gap on the rights side of the VS. The left side has a small gap and that's a design thing. The plans call for an AN960-10 washer underneath. The gap is caused by the offset of the VS to compensate for the torque of the prop.

I'm very satisfied with this modification and fortunatly all holes still line up well.

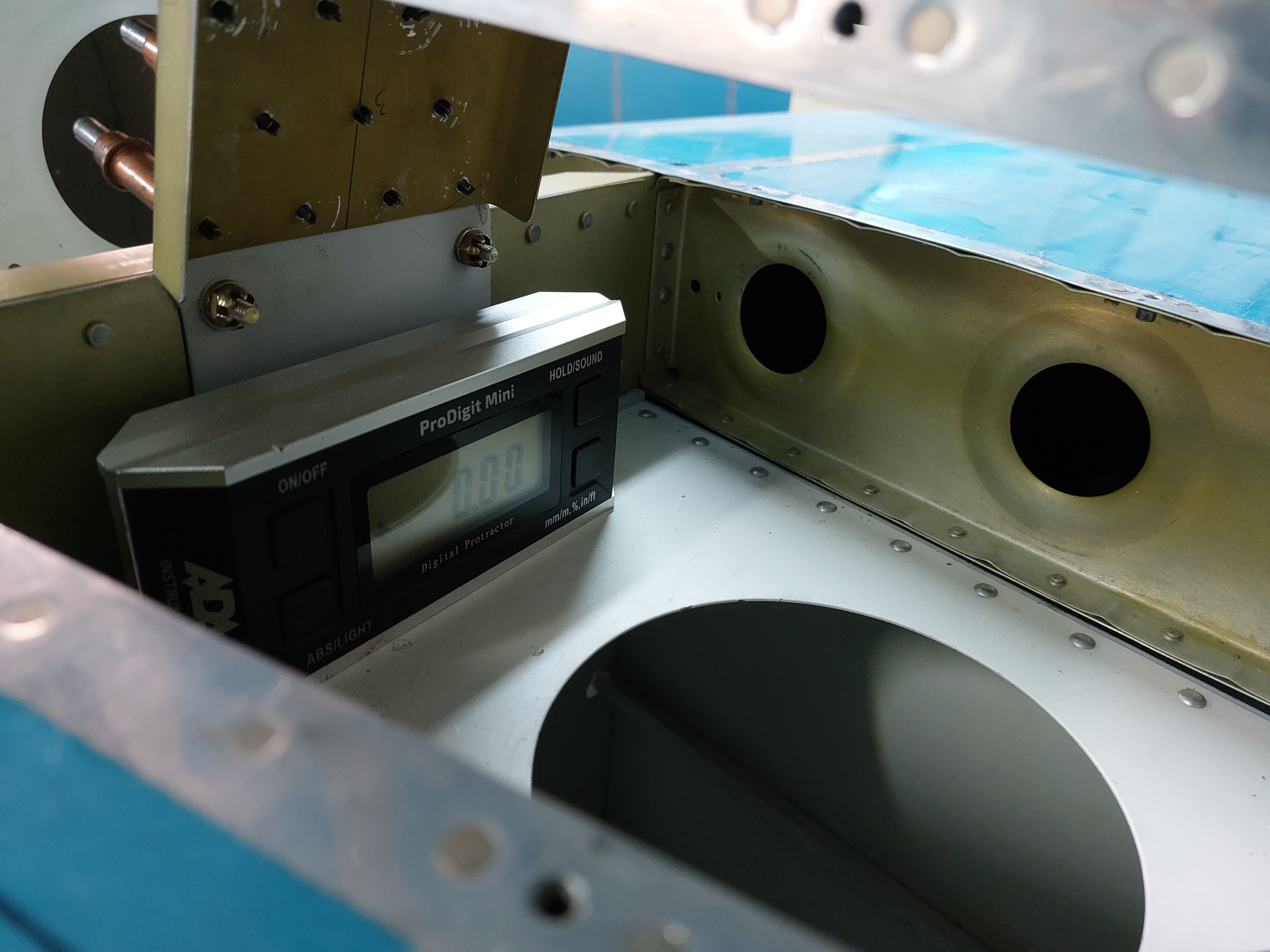

Next is the step of making sure everything is square and level again before I can drill the 2 holes in the elevator stop. Fuselage is straight and 0°, check.

Used some clamps to fixate the rear of the VS to F-712 rear bulkhead.

Then I measured the angle at the top of the elevator left and right.both measurement were 89.9°. Then measured with a tape measure the length between the top of the VS and the tip of the HS making sure the distance is equal.

Then used the existing hole in the VS (previously drilled) through the elevator up stop to define the new location of those holes and installed those bolts with temporary castle nuts.

Then measured distances again to ensure nothing moved. Yes , sometimes I want to be too precise and spend way to much time on this.

62 inch and 3/8 on left side.

62 inch and 1/4 on the right side. A difference of 1/8 which can probably be explained by the small shift in the direction of the VS with the washer.

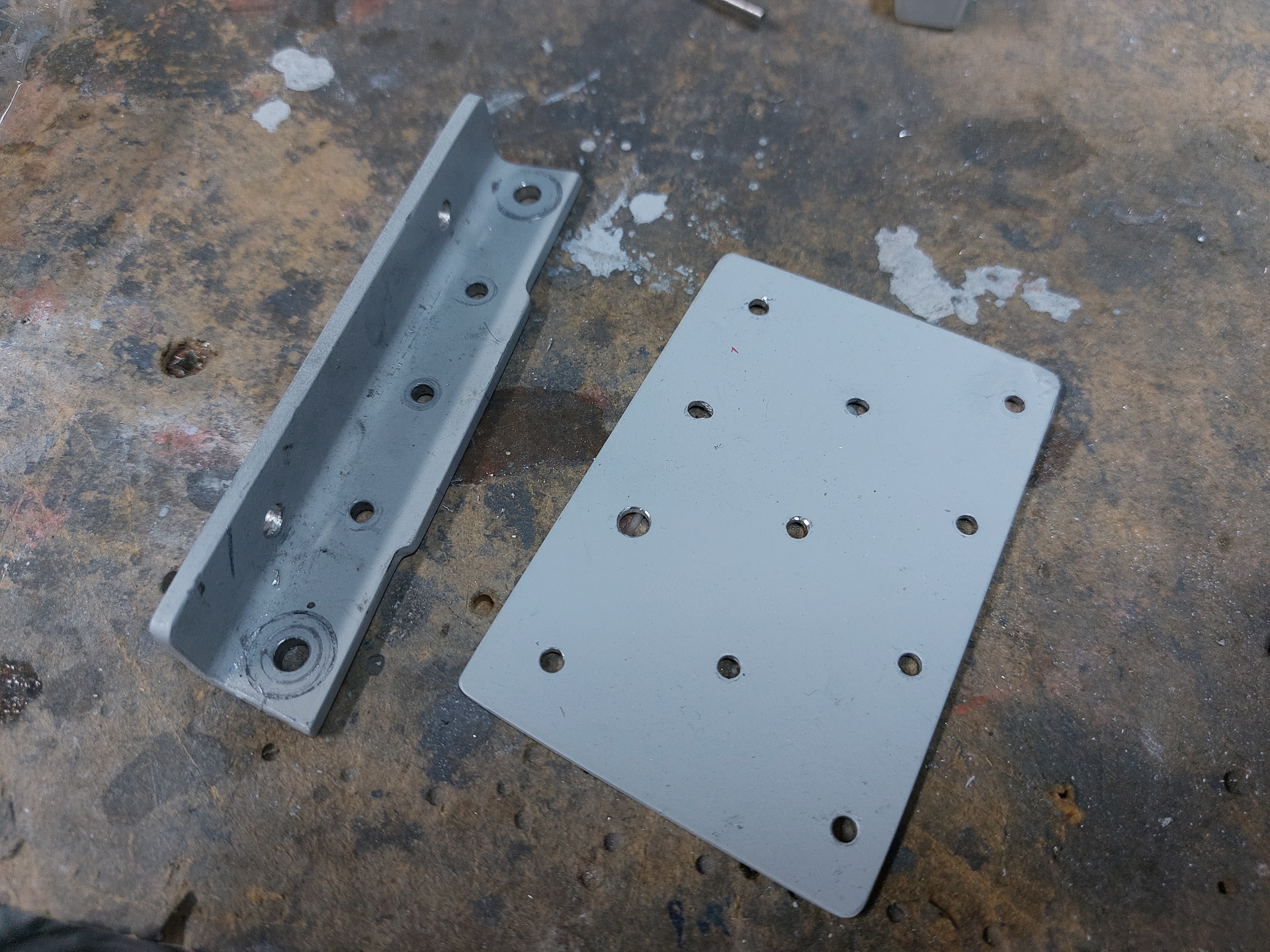

Lot of work done to get the result of the small piece below.

We reattached the rudder to check all aligments again. With all this done, I can probably start working on te VS and rudder fairing soon.

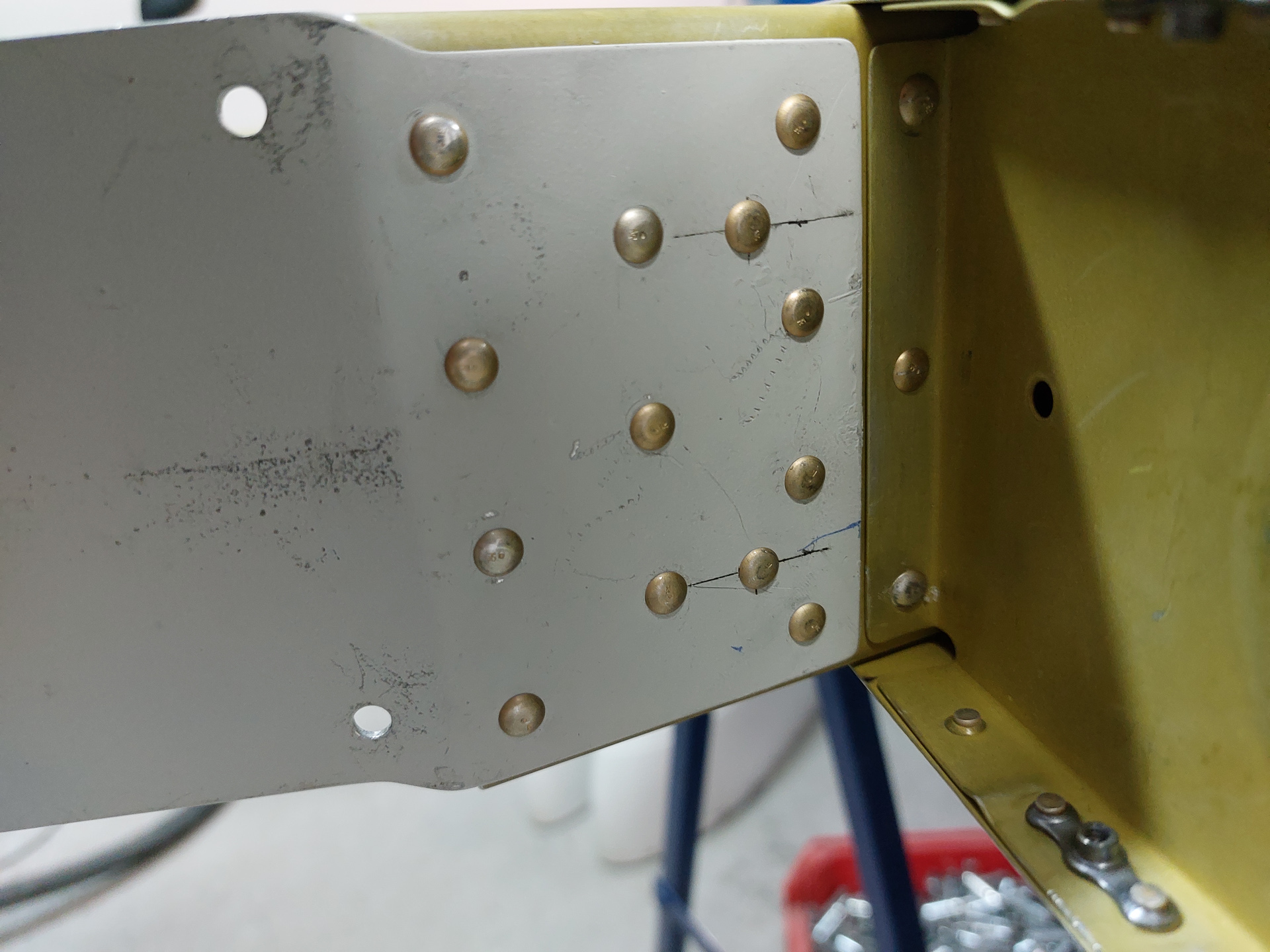

But first I had to rivet the F-781 back to the front spar of the VS. I had one hole which was badly drilled out near the top and which had an oval shape. I contacted Vans support about this and they advised me to place 2 additional rivets between the top and second row. for additional strength.

Rivets where all squeezed with the pneumatic squeeze. Even the hole that was elongated filled up nicely without any issues.

Here is the scrap material . The elongated hole is visible in the doubler here.